Automated Feeders Offer Explorations into New Management Practices to Improve Stillborn Rates

A 5,000-head commercial sow-farm research

Introduction

In modern sow farms, piglet mortality is the leading restraint in producers not reaching their maximum production potential. According to the last US national database evaluation performed by Dr. Stalder in 2018, the US had an industry average of ~26% pre-weaning mortality, with nearly 10% of those attributed to stillborn (Stalder, 2018). Perhaps this is rhetorical, but aren’t we as an industry underestimating the negative shadow this casts over us? To think that over 1/4th of fully formed pig fetuses will not make it to the next stage of production and 1/10th aren’t even born alive is absurd to me! So, what are we doing about it?

In animal agriculture if you want to make a change, you either have to genetically select for it, edit the genome, or introduce environmental changes (managerially, nutritionally, etc.). Changes in management are often easier and rear quicker results compared to genetic improvement, and in this study, we altered the time periods in which sows were allocated meals from the time they were loaded into the farrowing room until farrowings (the pre-farrow period). The thought process behind this is dated back to the late 1970’s at a Canadian ranch owned by Gus Konefal (Konefal, 1980). Konefal started feeding his cows into the late evening in hopes of the feed digestion process keeping them warm during the cold nights. Not long after he started doing so, he noticed a dramatic change in the percentage of cows that started to calve during the day (~50% to ~80%). To this day, it’s a common practice for cattlemen alike to feed their heavy bred heifers at night to make calving trend towards daytime hours when more assistance is available. Gestal/JYGA Technologies and a group of supporting casts (including myself) took this information and set up a study to see if this would translate to the swine industry. We hypothesized that by feeding sows in the early morning hours they would transition towards earlier farrowing onsets/completions times when there’s a higher staff attendance rate and ultimately reduce stillborn rates.

Materials and Methods

The current study took place at a 5,000-head farrow-to-wean farm in northeast Nebraska, USA owned by Standard Nutrition Company. At approximately day 113 of gestation, all sows were moved to farrowing; which had 18 rooms consisting of 56 crates per room. Upon entry to the farrowing crates, sows were randomly assigned to one of two treatments: Control (CTRL) – 100% of daily feed allocation from 7 – 10 a.m., and Alternative (ALT) – 100% of daily feed allocation from 2 – 5 a.m. Both groups were allowed a daily maximum of 5 lb each during the pre-farrow period. Quantity and feed delivery time were automated through the use of the Gestal Solo lactation feeders (JYGA Technologies, Inc.) Myself, along with two other technicians (Jenna Kibler and Megan Eickhoff) implemented a 24-hour farrowing surveillance schedule to track reproductive performance and timing. The time of the first observed piglet, the number of piglets at subsequent checks (~30 min), and the time the last piglet was observed were all recorded for each sow.

Results

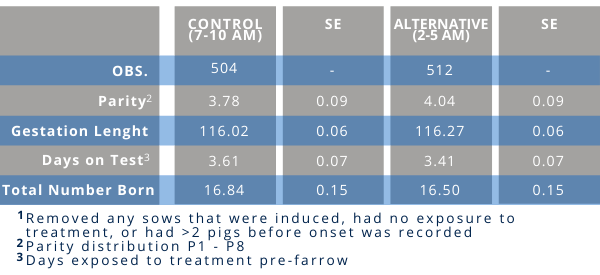

After editing the data, 1,016 commercial F1 sows of three predominant genetic lines were available for analysis. There was an even distribution of sows in both groups and low variances observed amongst traits that were used in the statistical models (Table 1), which allowed us to capture significant results.

Table 1: Summary Statistics1

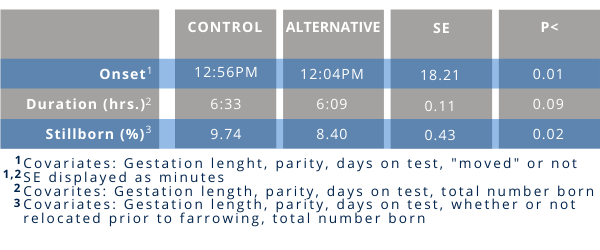

After accounting for various effects, we were able to estimate the least square means for our primary traits of interest (Table 2). We found that ALT sows farrowed earlier than CTRL sows (12:04 vs. 12:56PM, respectively). Sows on the ALT treatment also had shorter farrowing duration compared to CTRL sows (6:09 vs. 6:33, respectively). Most importantly, sows that were on the ALT treatment had lower stillborn rates than CTRL sows (8.40 vs. 9.74%, respectively). If you’re unsure on the significance of a 1.34% reduction in stillborn rate, just ask any producer what that change would do their production numbers and welfare persona. In addition to the results displayed, estimation of completion of farrowing can be calculated by adding duration of farrowing to the onset of parturition. On average ALT sows finished farrowing on average 1 hour and 16 minutes earlier than CTRL sows. This is vital since the majority of assistance is needed towards the latter end of the farrowing process. From this data, we can conclude that feeding sows earlier (2 a.m. vs. 7 a.m.) will result in earlier farrowings and reduced stillborn rates.

Table 2: Least Square Means1

Discussion

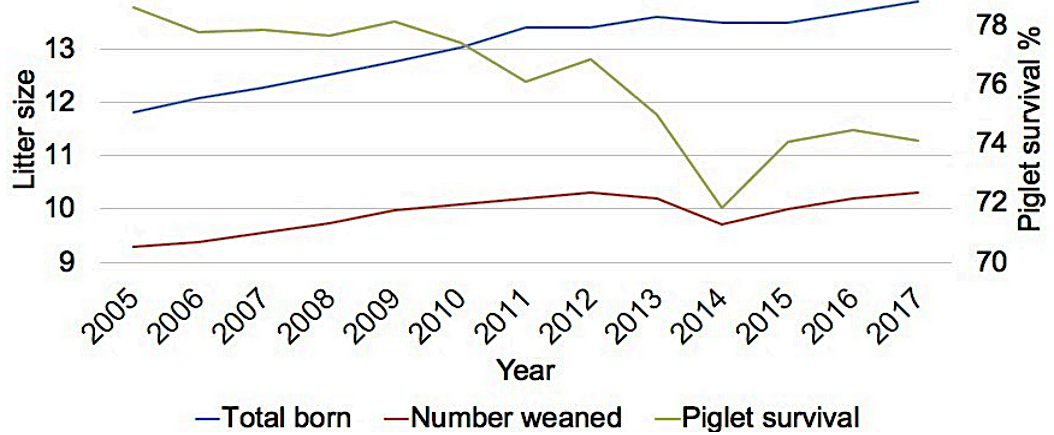

With the increasing welfare measures getting introduced across the US, why are piglet mortalities still above an acceptable threshold? One major factor is the genetic push in past years to improve the efficiency of sows by increasing the total number born per litter. In the graph below (Figure 1), you will see that this selection has been successful for larger litters at birth (blue line), but because there hasn’t been a linear increase in litter size at weaning (red line), piglet survival (green line) can be classified as THE limiting factor in maximizing reproductive throughput. In the current study we focused on stillborn rates, which is a portion of pre-weaning mortalities and are known to have a strong correlation with total number born. In a study conducted by Ketchem et al., (2019) where 410,000 farrowings were evaluated from 50 farms, they found a strong phenotypic correlation between the average number of stillborn per litter and total number born (R2= 0.795). The authors stated that this was expected and “makes sense, the more pigs she has the longer she is likely in labor and more likely to get tired which increases the time between pigs and increases stillborn” (Ketchem, 2019). The issues associated with increasing litter sizes aren’t disappearing any time soon, if anything they’re going to be amplified as we continue to push the envelope with production numbers.

Figure 1: US Swine Industry National Data Base

*2017 stillborn percentage was 9.85(±4.1)

Adapted from Knauer and Hosteler, 20132; Stalder, 2018

Currently, a high percentage of sows farrow overnight, unattended. Unattended farrowings mean no assistance is available when sows need it – which is the number one cause of stillborn (Ketchem, 2019). This also results in added stress on the sow, higher likelihood for retained piglets, greater chances for piglet crushing soon after birth and a longer recovery time for sows after farrowing. With this is mind, there are two options to mitigate unattended farrowings: 1) Implement 24hr farrowing staff or 2) Shift more sows to farrowing during daytime hours. With the ongoing labor crisis in animal agriculture, the sensible option is to manipulate the sows; we were successful in doing just that!

Although we were successful in proving our hypothesis, more work needs to be done before we truly understand the impact feeding time pre-farrow can have on parturition time and reproductive performance. In the current study, the ALT sows feed delivery time (2 a.m.) was not necessarily calculated – more so just an “educated guess” resulting from a small pilot study conducted at South Dakota State University. Perhaps feeding into the late evening, or midnight could move farrowings up even earlier in the day. However, the barrier with any alternative feeding method during lactation is the need for electronic feed delivery. Gestal’s lactation feeders (JYGA Technologies, Inc.) allow producers to feed their sows, with or without any farm staff present. It is also uncertain what the proper time period is for days exposed to treatment. In the current study, ~3.5 days was the average for days exposed to treatment prior to farrowing; perhaps more days would yield a greater response. In order for this to be feasible, feeding time would most likely have to be altered in gestation, which would be near impossible without some form of automated feeding. Fortunately, Gestal’s 3G (JYGA Technologies, Inc.) gestation feeders offer this capability as well.

As we continue to build upon our production methods in the swine industry while keeping an animal husbandry consciousness at all times, the use and integration of new technologies are essential. In the current study, I outlined a way such technologies could be employed to save more fully formed pig fetuses. This particular issue was the product of “single-minded” genetic selection for increasing production numbers, while lacking regard for any negative animal welfare association. Instead of retracting our selection advancements, managerial changes were utilized to mitigate those negative associations without sacrificing the end goal of raising more pigs with the same number of sows. For producers, employment of automated technologies will undoubtedly be considered a major factor in being sustainable going forward.

About the Author: Dalton Obermier, M.S.

I was born and raised in central Nebraska on a diversified farm where we raised and sold cattle, and pigs throughout my 4H and FFA careers. My roots have always been deep in animal agriculture so furthering my education in animal science was an easy decision. I attended the University of Nebraska to earn my Bachelors in Animal Science in 2018. From there, I moved halfway across the country to study Swine Genetics at North Carolina State University and ultimately received my M.S. degree in 2020. I am currently a PhD student at the University of Nebraska studying quantitative genetics under the direction of Dr. Benny Mote. Pigs always have, and always will be my main focus; as I hope to someday make a positive impact on the industry that has given me so much.

Literature Cited

Ketchum, R., Rix, M., and Duttlinger, V. 70% of stillborns come from 20% of sows; Who is at risk? National Hog Farmer Daily Update. June 5, 2019.

Knauer, M.T. (2013). US swine industry productivity analysis, 2005 to 20010. Journal Swine Health Productivity, 12(5):248-252.

Konefal, G. 1980. Daytime Calving – the Konefal Method. Ninth Annual Cornbelt Cow-Calf Conference, Ottumwa, IA.

Stalder, K. (2018). 2018 Pork Industry Productivity Analysis. Pork Checkoff, September 11, 2018.