Successful Farrowing Management: From Pigs to People

Managing farrowing units involves several correct decisions. Here are 10 great tips to help farm managers get the best results from sows, piglets, and employees.

FARROWING MANAGEMENT

Farrowing is one of the most challenging periods in pig production, since it can bring several risks if not well managed (Ruediger and Schulze 2012). For this reason, successful sow managers are committed to finding the best alternatives for improving productivity and profitability in their systems, as sow and litter performance is critical to the pig production chain (Vila and Tummaruk 2016).

The primary purpose of farrowing management is to improve the number and quality of weaned pigs per sow per year; simultaneously, it can allow sows an adequate return to post-weaning estrus. Thus, Kraeling and Webel (2015) highlight that farrowing management includes multiple procedures to ensure that sows and their litters perform well, including nutrition, environment, health, and animal behavior.

The success of all farrowing management depends on the people who are leading and executing the operations mentioned above. This means that high-quality employees are critical, since better results come from motivated and well-trained people.

Considering that farrowing management includes complex and multifactorial activities, this article highlights ten practical points to help farm managers improve overall performance and increase profitability in the farrowing units. Although employee performance has a great influence on the pigs’ results, the topics presented in this article were divided into two groups — pigs and people — to facilitate reading and help producers identify points that are critical in farm protocols.

MANAGING PIGS

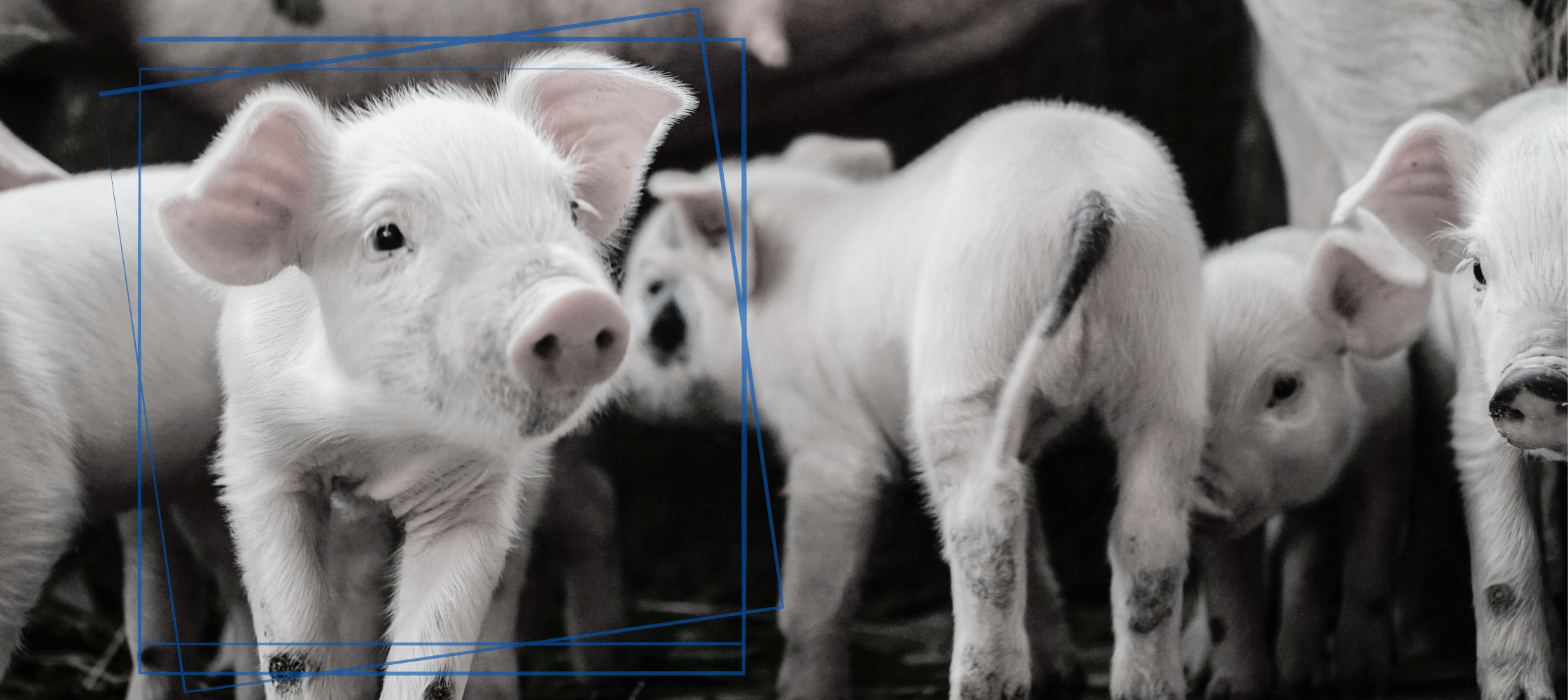

As Oliviero et al. (2009) highlighted, sows in the farrowing units give birth to many pigs in a relatively short period of time. This indicates that farm protocols must minimize sow health issues and ensure good performance while decreasing piglet mortality and improving the number of pigs per sow per year.

1. Sow’s Body Condition During Gestation and Lactation

It’s not news that avoiding extremes and fluctuations in a gestating sow’s body condition is one of the biggest goals of sow production, as it is related to poor performance (Beyga and Rekiel 2010). During lactation, weight loss is natural since the sow mobilizes energy reserves for milk yield. Wientjes et al. (2013) observed that body condition changes during gestation and that lactation could influence litter uniformity and piglet birth weight, affecting pre-weaning piglet survival.

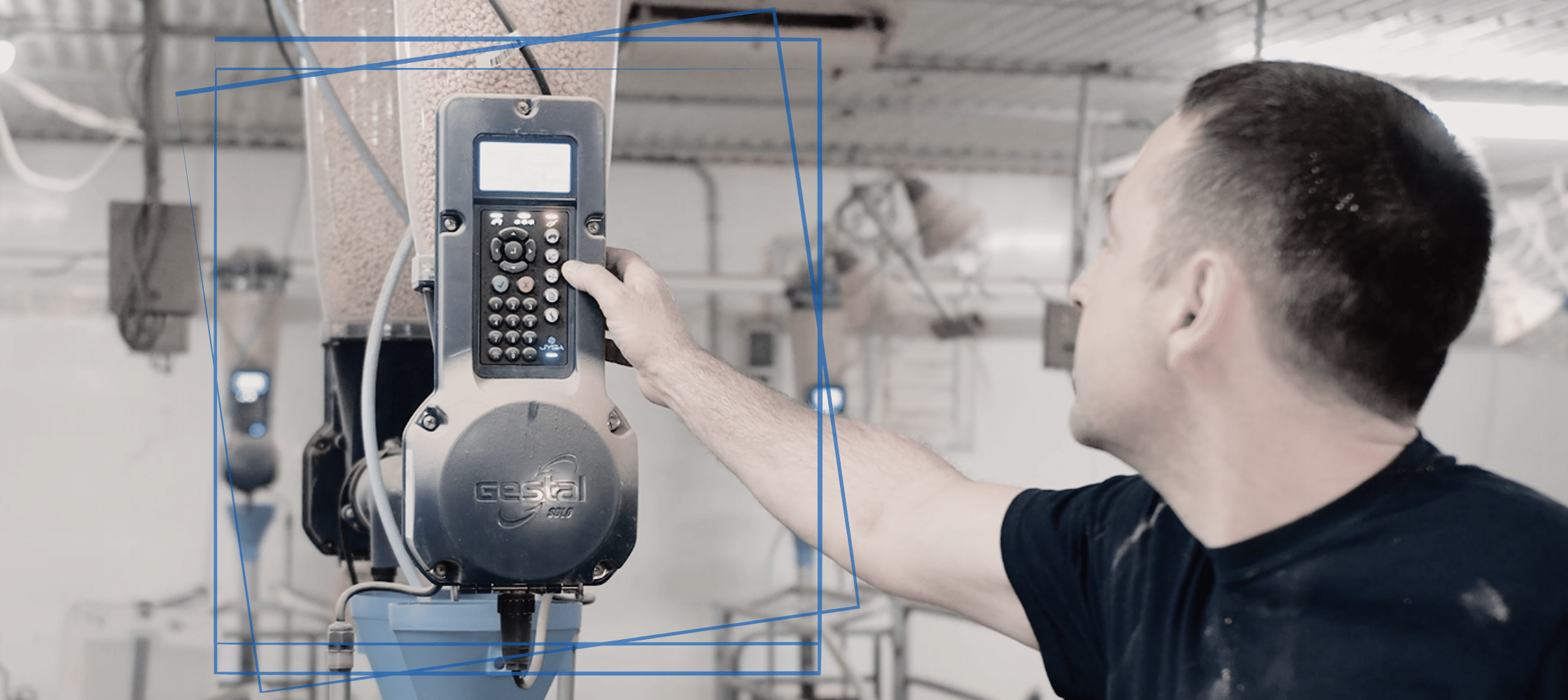

It is recommended that body condition assessment be conducted regularly and include all sows, which is not always achievable from a practical standpoint. As such, smart feeding systems have played an essential role in keeping the sows in a better body condition, since they consider that each animal is unique and has specific, individual nutritional requirements.

For example, Gestal 3G is a system for gestation sows in groups that individualize sow nutrition by feeding prescribed amounts or even blending multiple diets for each animal. Gestal 3G also tracks feed intake and offers automated and user-friendly reports that help farm managers improve individual sow body condition management and make more accurate decisions.

2. Sow Feeding Management

Sow nutrition during lactation can be challenging, since these animals require a lot of energy to produce milk and consequently wean a greater number of piglets. Therefore, adequate farrowing management must include operations to measure and improve sow feed intake, which is directly linked to milk production and litter performance. Two essential practical strategies include offering full feed Both techniques are well known for improving sow feed intake and maximizing litter growth but require extra labor when done manually. (Lynch 2001; Cools et al. 2014; Peng et al. 2007).

By recognizing the importance of sow feed intake for the farrowing unit’s overall performance, electronic feeders changed the traditional way of measuring animal feeding behavior, which can now be based on data collection and analysis. Like the Gestal smart feeders, high-tech electronic systems allow on-demand and wet-dry feeding that, in addition to improving sow performance, also minimizes feed and water wastage and spoilage (Peterson et al. 2004).

3. Attending the Sows

Evaluating the sow is always part of any farrowing unit’s procedures, and this needs to be done constantly. Health issues may occur during farrowing, which is sometimes inevitable. However, farrowing operations must be guided by straightforward protocols to treat sick animals and minimize disease issues such as fever, anorexia, vulval discharges, and mammary gland disorders. Tummaruk et al. (2013) points out that sick animals have a lower appetite, suggesting that feed intake is a sign of how well sows are performing. Thus, daily reports from electronic feeding systems, like Gestal smart feeders, are an essential tool to help managers identify when sows are not exhibiting their regular feeding pattern, indicating a possible health issue.

4. Early Care of Piglets

Piglets also have to be well–managed to maximize farrowing unit success. The hours after birth are critical in the pigs’ life, and early assistance can improve piglet survivability. Piglet early care procedures differ from farm to farm. However, the farm protocols must be well designed and executed. As Devillers et al. (2011) and Muns et al. (2015) point out, colostrum intake in the first twenty-four hours of life is a determinant for piglet survival. Techniques such as split nursing can be used to make sure all piglets have access to colostrum. Any movement of piglets needs to be performed as quickly as possible, before teat order is established.

5. Preparing Farrowing Units

Farrowing operations start days before sows enter the units. Farrowing facilities, or at least the pens, must be disinfected and cleansed of any organic matter 5 to 7 days before a new group of sows gets settled. Equipment such as hot boxes, lamps, and mats also need to be correctly cleaned, dried, and disinfected.

Another essential measure regarding setting up the units is environment control. Farrowing sows and piglets have different warming demands: the ideal temperature range for sows is between 64ºF to 73ºF and for the piglets 86ºF to 89.6ºF (Caldara et al. 2014). There are many strategies for mitigating or minimizing heat stress effects during farrowing. Sophisticated feeders, like the Gestal Quattro, also manage the piglets’ environments daily and reduces electricity demands by adjusting heat curves based on the farrowing date.

Other tips worthy of mentioning are: ensure the farrowing units are calm and quiet places, that all supplements are ready to use, the equipment is working, and ventilation is adjusted properly based on age of pigs.

Moreover, well-designed facilities with high-quality equipment are essential for improving farrowing performance. All smart feeders from Gestal, for example, are engineered with strong, durable products. Gestal feeders are also easy to implement and can be adapted to any building type or size.

MANAGING ON-SITE EMPLOYEES

Many swine producers and managers agree that modern pig production is less about pigs and more about people management. That is true when it is noted that the social interactions between employees answer many questions as to how the farrowing units are performing.

6. Number of Employees per Unit

Although there are many recommendations regarding the number of employees required in the farrowing units, it’s worth highlighting that it can vary from farm to farm. That variation occurs because the number of employees per unit is closely related to farm production goals and metrics. If the farrowing units’ primary purposes are a greater number of pigs weaned/sow/year and lower pre-weaning mortality, it will demand more labor. Furthermore, the level of technology in the farm also influences employees’ numbers and tasks (Piñeiro et al., 2019).

For example, using automatic feeders for farrowing can increase labor efficiency by promoting actions based on data. The Gestal smart feeding reports help employees find the sows that need assistance with precision: they can check on a computer or smartphone if any of the sows didn’t eat during a specific period and then go straight to those individuals. Besides, the reports can also eliminate manual tasks, such as hand feeding and getting every sow up, which provides more time for employees to handle other activities. The main goal of these technologies is to help good employees go a lot further.

7. Optimized Work Schedules

Many activities are going on simultaneously in the farrowing units, including sow and piglet feeding management, animal health monitoring and treatment, and routine operations such as vaccination programs, facility maintenance, cleaning, and disinfection. With all these tasks to handle, Martel et al. (2008) suggest that employees’ life becomes easier when clear and compelling schedules guide them and their workload is well distributed. Maintaining clear work routines leads to precise results. The same is true regarding the number of employees: each farm has unique demands and goals, and work schedules must fit the farm’s needs.

Practical tips for improving work schedules are: register daily and weekly work routines, review and change the goals regularly, and save time in the farm’s operations for possible emergencies (disease treatment, repairs, etc.).

8. Effective Communication on the Farm

As farms become larger, managing people becomes more complex because greater numbers of employees lead to communication issues. However, there are some tips for improving team communication. One of them is valuable and constructive feedback, thereby inspiring employees to do their best by providing a deeper understanding of their responsibilities and expectations.

Another is implementing visual communications in the farrowing units, as many people in the U.S. workforce do not have English as their first language (Durst et al., 2018). Like the smart feeders from Gestal, some equipment optimizes farm communication, as issues in sow feed intake are indicated by different easily interpreted colors.

9. Training Opportunities

Staff training is critical when managers want to keep employees motivated, and there are many ways to do that. When a new employee is hired, onboarding is crucial for understanding the farrowing procedures and the farm work routine. On the other hand, continuing education opportunities are very welcome for long-term employees, helping them improve and develop their careers. Besides, as technology levels gradually increase in the farrowing units, fewer employees are needed in manual heavy labor, such as feeding sows by hand (Piñeiro et al., 2019). Thus, the farmworkers can optimize the farrowing operations and develop critical skills by analyzing data recorded from the electronic feeders and building accurate individual sow feeding strategies. User-friendly platforms for data analysis accompany Gestal smart-feeders, which helps employees with their decision-making process.

10. Measuring and Increasing Labor Quality

Every farrowing unit is unique and has individual demands that will influence how employees are managed. Given this fact, sow farm managers need to find metrics to evaluate how their team is performing. Production metrics, such as farrowing rate and pre-weaning mortality, can be an indicator of labor quality. However, human-based metrics are also necessary.

Moreover, improving labor quality is not an easy task, since many US farms face employee turnover rates of over 100% per year (Marchand et al., 2008). People also don’t want to work every weekend and more than 40 hours per week. The biggest tip here is precise: make employees’ lives easier and better. Bringing new technologies onto the farm will most definitely help in this regard.

Technology is already part of a pig farm’s daily routines and can also help increase retention rates on the field and encourage young people to apply for jobs in the swine industry. Many of the changes in farm systems have been led by the next generation of swine producers, which now see the great opportunities and benefits in pig production that are provided by technology adoption.

CONCLUSIONS

Sow producers and managers know many of the hot topics presented in this article firsthand. However, when these multiple operations in the farrowing units are offered as guidelines, it can help them figure out critical points in farrowing management that require some adjustment. By locating these points, it is possible to set priorities and make more assertive changes in the system.

Some of improvements can positively impact many of the above-mentioned topics. For example, Gestal offers several options for electronic feeders that help managers to optimize overall farrowing numbers. Their smart feeders improve sow performance by offering data-driven reports, which permit attending to specific sows’ demands. Those reports also indicate possible health issues when sows are not following their regular feeding pattern.

Besides, smart feeders like Gestal also make employees’ lives better and easier, as they minimize heavy and manual labor and include user-friendly and straightforward software with real-time monitoring.

Finally, successful management in the farrowing units is only possible when the decision-making is based on data acquisition and analysis instead of observational and abstract attitudes.

Technology brings powerful tools that positively impact sows and piglets’ performance and improve the quality of life of the people on the farm.

Literature Cited

Beyga, K., & Rekiel, A. (2010). The effect of the body condition of late pregnant sows on fat reserves at farrowing and weaning and on litter performance. Archives Animal Breeding, 53(1), 50-64. https://doi.org/10.5194/aab-53-50-2010

Caldara, F. R., Dos Santos, L. S., Machado, S. T., Moi, M., de Alencar Nääs, I., Foppa, L., … & Dos Santos, R. D. K. S. (2014). Piglets’ surface temperature change at different weights at birth. Asian-Australasian journal of animal sciences, 27(3), 431.

Cools, A., Maes, D., Decaluwé, R., Buyse, J., van Kempen, T. A., Liesegang, A., & Janssens, G. P. J. (2014). Ad libitum feeding during the peripartal period affects body condition, reproduction results and metabolism of sows. Animal reproduction science, 145(3-4), 130-140.

Devillers, N., Le Dividich, J., & Prunier, A. (2011). Influence of colostrum intake on piglet survival and immunity. Animal, 5(10), 1605-1612.

Durst, P. T., Moore, S. J., Ritter, C., & Barkema, H. W. (2018). Evaluation by employees of employee management on large US dairy farms. Journal of dairy science, 101(8), 7450-7462.

Kraeling, R. R., & Webel, S. K. (2015). Current strategies for reproductive management of gilts and sows in North America. Journal of Animal Science and Biotechnology, 6(1), 1-14.

Lynch. P. B. (2001). Factors affecting voluntary feed intake in the sow during lactation period. PhD Diss. National University of Ireland, Dublin, Ireland.

Marchand, L., Boekhorst, J., & McEwan, K. (2008). Human resource needs assessment for the Pork Industry. Ontario Pork Industry Council and University of Guelph, Ridgetown Campus.

Martel, G., Dourmad, J. Y., & Dedieu, B. (2008). Do labour productivity and preferences about workload distribution affect reproduction management and performance in pig farms. Livestock Science, 116(1-3), 96-107.

Muns, R., Manteca, X., & Gasa, J. (2015). Effect of different management techniques to enhance colostrum intake on piglets’ growth and mortality. Anim. Welf, 24, 185-192.

Oliviero, C., Heinonen, M., Valros, A., & Peltoniemi, O. (2010). Environmental and sow-related factors affecting the duration of farrowing. Animal reproduction science, 119(1-2), 85-91.

Peng, J. J., Somes, S. A., & Rozeboom, D. W. (2007). Effect of system of feeding and watering on performance of lactating sows. Journal of animal science, 85(3), 853-860.

Peterson, B. A., Ellis, M., Wolter, B. F., & Williams, N. (2004). Effects of lactation feeding strategy on gilt and litter performance. Journal of Animal Science, 82, 65-65.

Piñeiro, C., Morales, J., Rodríguez, M., Aparicio, M., Manzanilla, E. G., & Koketsu, Y. (2019). Big (pig) data and the internet of the swine things: a new paradigm in the industry. Animal Frontiers, 9(2), 6-15.

Ruediger, K., & Schulze, M. (2012). Post-farrowing stress management in sows by administration of azaperone: Effects on piglets’ performance. Journal of animal science, 90(7), 2331-2336.

Tummaruk, P. (2013). Post-parturient disorders and backfat loss in tropical sows in relation to backfat thickness before farrowing and postpartum intravenous supportive treatment. Asian-Australasian journal of animal sciences, 26(2), 171.

Vila, R. M., & Tummaruk, P. (2016). Management strategies in farrowing house to improve piglet pre-weaning survival and growth. The Thai Journal of Veterinary Medicine, 46(3), 347.

Wientjes, J. G. M., Soede, N. M., Knol, E. F., Van den Brand, H., & Kemp, B. (2013). Piglet birth weight and litter uniformity: Effects of weaning-to-pregnancy interval and body condition changes in sows of different parities and crossbred lines. Journal of animal science, 91(5), 2099-2107. https://doi.org/10.2527/jas.2012-5659