OWNER:

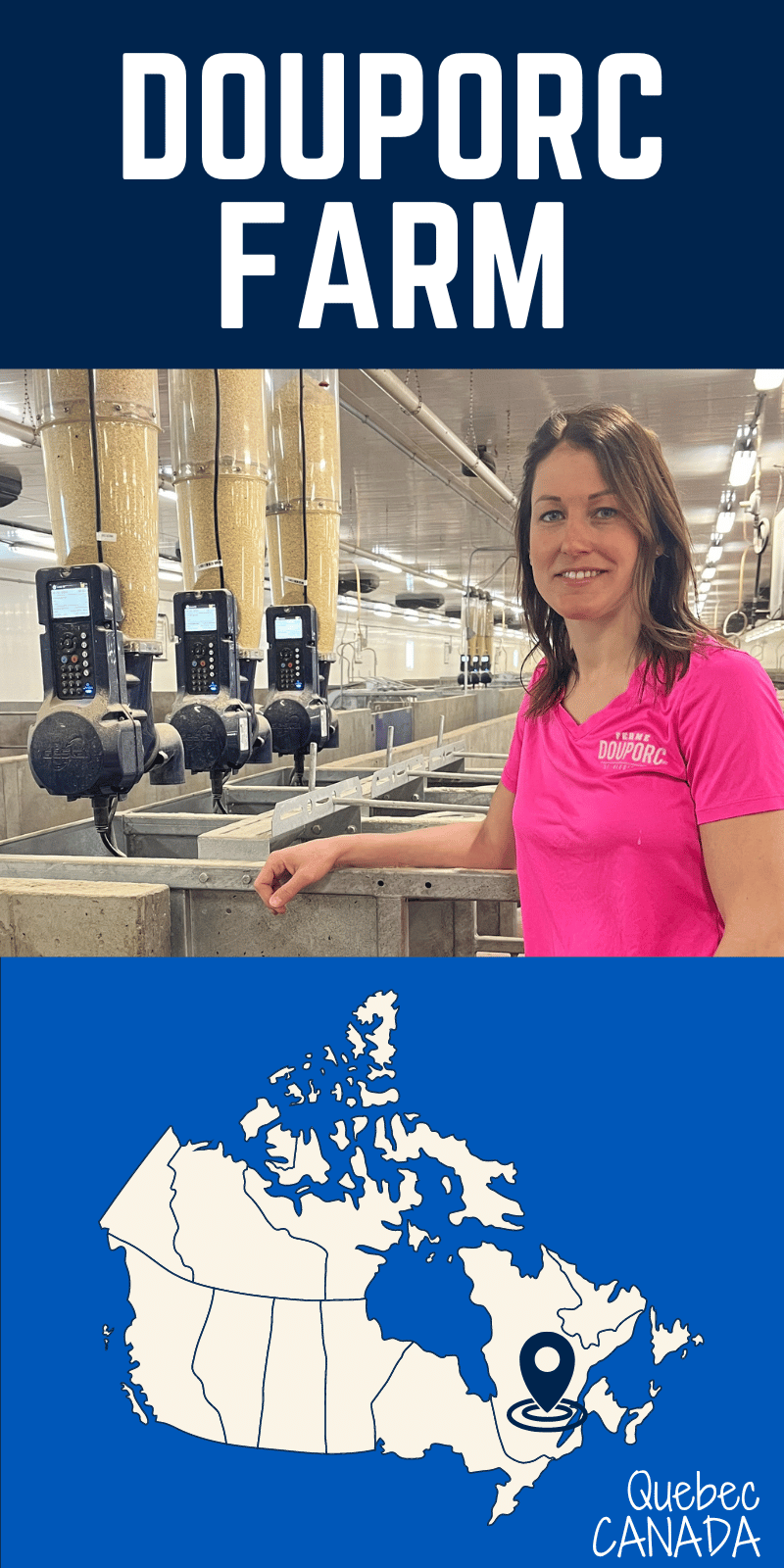

Andréanne Wolfe

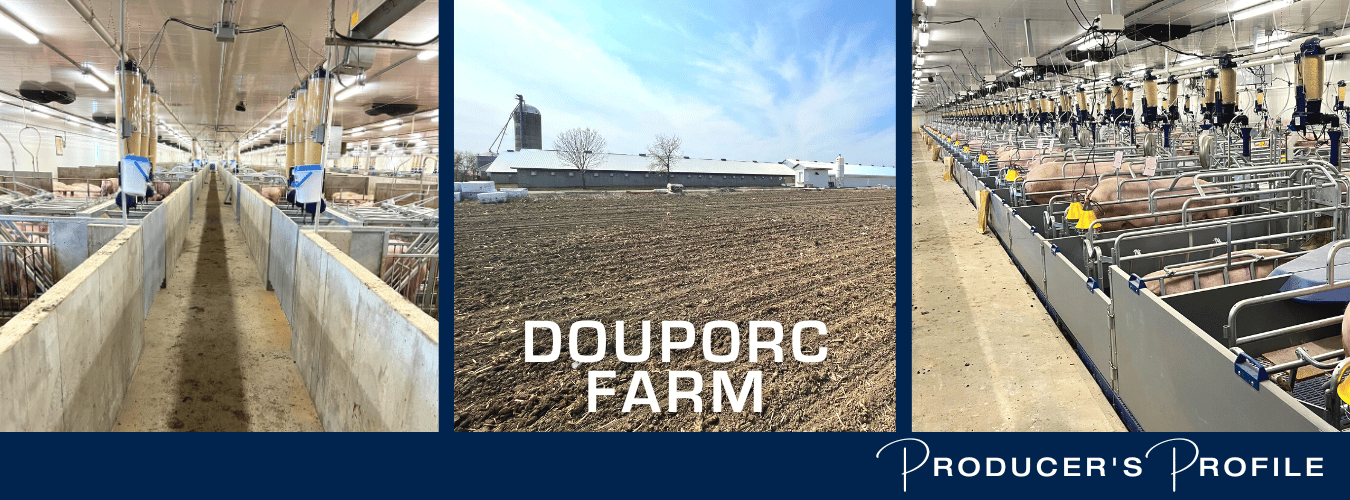

Saint-Alexis, Quebec, Canada

Farm’s Features:

-

1,700 sows farm, 2 week batch farrowing

-

Douporc Farm uses corn and soybeans grown on the family land to feed its sows

- 3 full time workers and 2 part time employees

-

Gestating sows are fed with GESTAL 3G while lactating sows are fed with GESTAL Quattro and GESTAL FM

With GESTAL feeding systems, the farm was able to save nearly 15 hours per week for sow care.

Reduction of 10 hours per week for data entry tasks.

The Wolfe Family Has Chosen GESTAL Feeding System for Over 20 Years

As a daughter of agricultural producers who was raised around animals since childhood, it was natural for Andréanne Wolfe to become the owner of her own farm. In order to deepen her knowledge in the field, she decided to pursue her college studies in agriculture at McGill University’s MacDonald Campus. In 2010, she decided to take a big step and bought Douporc Farm, becoming the third generation in pork production.

Taking over another producer’s business with vacant facilities was just as much of a project as starting a new building. At the time of purchase, the facility consisted of a 650-sow farrowing facility. After managing the business for almost three years, Andréanne proceeded with renovations by enlarging the space dedicated to sows and removing the nursery, to increase the herd to 850 sows.

The Interest in a Technology Passed on from Father to Daughter

December 2020: Technology for the Farm

Andréanne is a persistent and a forward-thinking person who thrives on new projects, just like her father! She grew up with one of the first generations of GESTAL precision feeding systems, the GESTAL FM, which was installed on the farm owned by her parents, Carole and Gaston Wolfe. Through this experience, Andréanne was already convinced of the advantages of the equipment and the possible returns on investment.

This is why, following its renovations, Douporc Farm integrated the new generation of precision feeding systems; the GESTAL 3G for gestation as well as the GESTAL Quattro, which additionally controls the lamp and the heating mats for farrowing. At the same time, the VISION software was added, allowing to collect precise data regarding swine feeding and herd management.

A Feeding System that Saves Time and Effort

For the dedicated owner, the acquisition of the GESTAL technology and VISION software was a choice that seemed adventurous at first, but it turned out to be a wise one.

This significant project ensured the stability of her equipment for the following years. At the same time, it would also allow her to save a lot of time by not having to feed the animals manually.

«I really save a lot of time in entering breeding data! » - Andréanne Wolfe

In addition, Douporc Farm has noticed a reduction in the number of hours spent transcribing data, since each feeding system automatically and quickly transfers data to the farm’s computer via a Wi-Fi connection.

Quick Identification of Sows in Need

As soon as she arrives at the farm, the young producer checks and analyzes the data collected via the feeding system. Using an RFID reader stick and the VISION software, she can easily identify sows that have not eaten properly, or that have lost their RFID Tag, both in the farrowing and gestation sections. She adjusts, directly from her phone, in order to regulate the curve of the identified sows.

Lactating Sows: The Heart of the Farm’s Operations

Following a fire in 2020, where two farrowing rooms were completely lost, Andréanne had to rebuild. However, she was able to take advantage of the situation to add 28 GESTAL Quattros. Douporc Farm now has a total of 144 GESTAL Quattros in farrowing. This division has always been very important to the owner. She has paid special attention to it for many years. That’s why it made sense to choose the GESTAL Quattro, given the advantages it has, especially the ability to control the heat lamp in farrowing and the heat mat remotely. The fact that this feeding system could stimulate feed intake, reduce waste, facilitate sow management and manage the piglets’ comfort zone suited her perfectly. With the right setup according to birth dates, the heat lamp and heat mat, connected to the GESTAL Quattro, turn on and off according to the scheduled and recorded time. Since everything is automatically controlled, the company can make the time spent on managing the food supply more profitable.

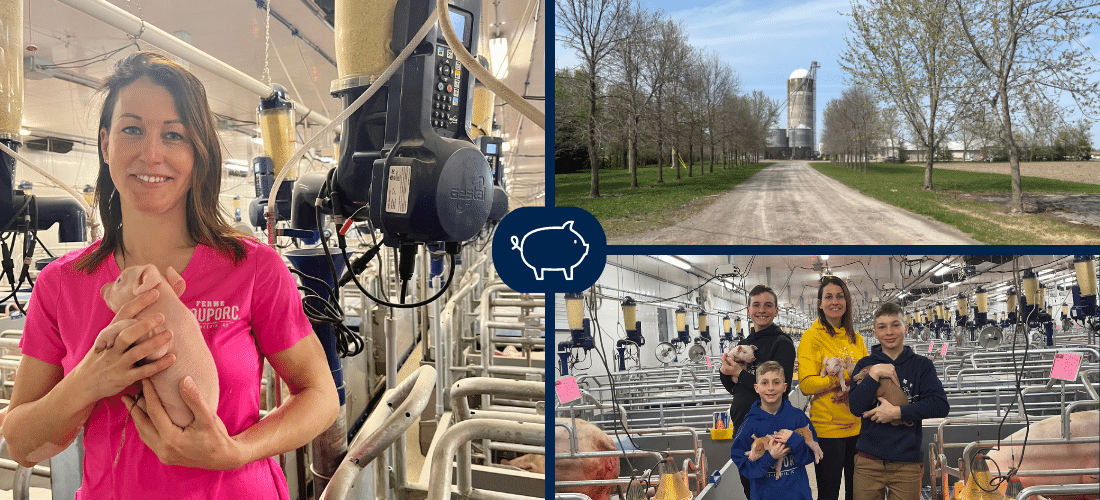

Most farrowing at Douporc Farm are done on Wednesdays and Thursdays every two weeks. One week in weaning and one week in farrowing. More than 1,700 piglets leave the farm every two weeks. A portion of the piglets are sent by an external carrier to the family farms, which have facilities dedicated to finishing. The other pigs are sent to a neighboring farm.

Addition of a Pen for Group-housed Gestation Sows

At the end of December 2021, the company proceeded with the installation of its first 72 GESTAL 3G stations, simultaneously with the entry of the first group-housed gestating sows. This feeding system is easy to install and very adaptable to newly built farms. Since the nutritional needs of sows change during gestation and the feed intake has to meet the demand, the company can rely on the GESTAL 3G to feed the sows individually, according to their needs, and at a lower cost. Group-housed gestation allows the sows to have more space, therefore reducing aggression and stress.

Increasing the herd and adding new equipment can be an additional source of stress for the animals. These changes also lead to new training for the sows and gilts. First, the sows had to get used to the change in texture of their new pelleted feed since they had always eaten ground feed. They were not used to hearing the pellets fall from the feeder.

However, adapting to the GESTAL 3G is much easier than with a traditional feeder. It was only after a few meals that the gestating sows were accustomed to the system. They are now completely trained, and can enter the 3G station, isolating themselves from the rest of the pen, and safely consume their customized meal. Thus, the GESTAL 3G meets animal welfare standards without compromising the farm’s performance.

Using Precision Feeding Systems for Sows, a Daily Teamwork

For more than a year, Andréanne was in charge of the management of the breeding every day. In order to have more time to devote to her other obligations as manager of both her farm and her parents’ farm, and considering the fact that the workload was high for only one person, Andréanne decided to share her knowledge and train her employees for breeding. She was able to delegate some of the tasks to her three employees who work on the farm, foreign workers from Guatemala. They are working full time and manage the herd: two people for farrowing and one person for breeding. Andréanne considers herself very lucky to be able to count on them. They are very hard working. They follow up on the farrowing early in the morning and late at night. There are also two other part-time employees who come in to help with the daily tasks on weekends.

Andréanne has been working with foreign employees for over 8 years now. Some of them now speak a little French and the young producer has, over the years, learned Spanish.

Grand Ideas!

Andréanne takes care of the internal management, her father brings his expertise related to the farm equipment while the employees jointly carry out the daily tasks. Andréanne is very proud to see her business grow despite the challenges of rising costs. It is not impossible that Douporc Farm will grow over the next few years.

In the future, if the opportunity comes up, the young owner would like to buy her parents finisher, allowing her to become a fully integrated farrow-to-finish operation. A few acres of land could also be added to the company’s holdings. Andréanne has three young boys who love agriculture. Who knows, maybe one of them could join the team eventually.

In the end, they all have common goals; to make the business effective, control costs and have a healthy herd.

For more information on GESTAL precision feeding systems, contact our experts or call us at (866) 333-7853. With over 25 years of experience in swine production, we know your reality. GESTAL products are sold worldwide, including Canada, the United States, Latin America, Europe and Asia.