Precision Feeding as a Modern Solution for Swine Feeding to Individual Requirements and Capturing the Most Value in your Farm Operation.

By : Amanda Uitermarkt

The Banff Pork Seminar is a technology transfer meeting for the pork industry that has been held in Banff, Alberta, Canada since 1972. The conference program is coordinated by the Department of Agricultural, Food & Nutritional Science, University of Alberta, in cooperation with Alberta Pork, Alberta Agriculture and Forestry and other pork industry representatives.

Jyga Technologies was invited to give on presentation about various swine feeding solutions available to pork producers. You can view the presentation below.

For the Q&A session of the presentation, click here.

Here is the transcript of the presentation.

Jyga Technologies: Swine Feeding Solutions

For those of you who are not familiar with JYGA Technologies, one thing that sets our company apart is that all the way up at the ownership level, we are pork producers first. JYGA owners are also swine farm owners, managing a 2,300-head sow farm that serves as a research and beta test site for all Gestal products prior to market rollout.

In the 25+ years of JYGA Technologies, we have several generations of feeding equipment across various stages of swine production. Our flagship lactation products have been on the market since 1994, but we entered the gestating sow (or group housing) arena in 2014, and the nursery/grow-finish/gilt development arena in 2019.

As a matter of clarification, you will mostly hear me refer to the Gestal product line, which is owned by JYGA Technologies. We are continuing to add to products offered under the JYGA umbrella.

In short, our owners and management team have a clear understanding of commercial production, and they are taking it into consideration every step of the way.

The Gestal Smart Feeder – a Technology that you Can Rely on!

The foundation of Gestal is based on advanced pig farming. Our owners were and still are users of JYGA products prior to purchasing the company, and our advances in technology are the culmination of their efforts to both improve their own operation, as well as those of others. As with any meaningful piece of technology, the key is collecting that data surround us and using the correct tools to analyze this data in a meaningful way.

Gestal software and swine equipment feed to the precise needs of an animal or group of animals and automatically draws user attention to animals who need assistance. We have 4 major areas of expertise that I will try to briefly touch on today: Gestation, Lactation, Grow-finish/GDU equipment, as well as our newest venture into herd management, our Vision software platform.

Feeding System for Gestating Sows in Groups

For several years now, producers have been trying to find the ideal system for feeding to the requirements of the individual animal while in a group setting. Several traditional ESF’s have adequately performed this function, but at a cost of intensive gilt training, many moving parts that require maintenance, and a considerable amount of competition within pens.

How to Avoid Competition for Feed?

The Gestal 3G system was designed to combat all these issues and provide a low competition, low maintenance solution to feed to individual animal requirements. Our smart sow feeding system is operated entirely by the sow and provides a secure feeding location until the animal has finished her meal. The RFID technology ensures that each animal receives the precise amount of feed allotted.

The Gestal 3G offers group housing for sows with minimal competition for feed. While traditional ESF’s can feed up to 60 animals per station, Gestal 3G stations are intended for use with 15-20 animals each, drastically reducing competition and increasing flexibility in pen design and layout.

Ensure the Right Body Condition When Leaving Gestating Pen

Ensuring correct body condition at the time animals enter the farrowing house is an imperative step in getting the most value out of your operation.

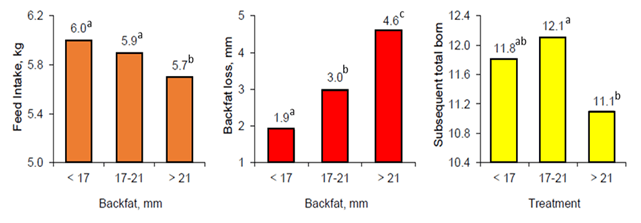

Over-conditioned animals leaving gestation parks are costly because we have invested in additional feed, but as the data shown here by Young and others demonstrates, over-conditioned animals also consume less in lactation and may have decreased subsequent total born.

Some of the common causes for over-conditioned sows leaving gestation are:

- Overfeeding a whole pen to improve body condition in thin sows (which is common in floor feeding or stanchion feeding)

- Failure to properly calibrate feed drops or ESF’s.

- Improper scoring by staff

The Gestal 3G system wirelessly shares calibrations between feeders, making the calibration process much easier to accomplish routinely.

Use of the Gestal mobile app makes an easy task of assigning or changing body condition score or feed amounts.

Feed Blending in a Gestation Room

As a last point before we leave the gestation topic, some systems are now capable of altering the diet on a daily basis to match changing sow requirements.

Imagine a scenario where we have access to 2 diets at each feeder that we can blend in gestation: a high-protein diet and a lower protein maintenance diet.

Since we know that sow amino acid needs are the highest in late gestation, should we be blending feeds during gestation to save on diet costs during periods of low requirements?

Additionally, the use of smart software can implement curves that adjust automatically. For example, if an animal is thin at the beginning of gestation and is assigned additional feed, the curve could be set to automatically adjust downwards to the ideal body condition feeding level after a period of time when the animal body condition should be corrected. This could allow skilled workers’ time to go further if less body condition checks are required.

Gestal 3G software and equipment are both capable of and already are performing these tasks.

Feed Management During Lactation

To switch gears and discuss opportunities to improve production in lactation, our flagship lactation equipment is known for the ability to feed and analyze intake patterns based on parity or genetics. We have lactation feeder models that vary from simply feeding sows, to also controlling heat mats or heat lamps, as well as some that allow for feed blending in lactation.

Introducing Three Lactation Feeding Solutions

The Gestal Focus is our newly designed base-model feeder, featuring LED lights that coordinate with sow consumption so that barn workers can easily identify problem or low consumption animals. The Gestal Solo features a screen with exact intake information as well as LED indicators, and the Gestal Quattro additionally allows for feed blending as well as control of heat mats or heat lamps.

It is important to remember that, the lactation software with automatic detection of low consumption as well as potentially limited or wasteful animals comes standard on all Gestal lactation feeders. The interface of the feeders may look different, but the Gestal feeding advantage comes standard.

Precision Feeding as a Feeding Strategy

Gestal products are precise enough that they can be used in research situations. With feed blending in lactation, we can pursue things like the use of transition diets and blending to change nutrient density as lactation progresses to conserve diet costs when nutrient demand is lower.

The Gestal Quattro is capable of feed blending, controlling heat mats or heat lamps, dosing water and feed simultaneously, and this hopper design can mount on up to 4 feed lines.

All Gestal lactation feeders use a trigger for the animal to request meals, small stimulation portions to let sows know that a meal is available, and our software automatically generates reports to quickly identify limited or wasteful animals, as well as those who are off feed. How much money would it save your operation to identify sick animals even 1 day earlier in lactation?

Focus your Attention on What Is Important

In addition, Gestal reports can help your operation “manage by exception,” or focus time and skilled labor on animals that need attention.

As I mentioned, automatic reports based on producer preferences will direct your attention to both low consumption animals, as well as those that are requesting suspiciously high amounts of feed.

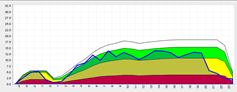

As you can see in these graphics exported directly from our software (see below), we use color codes to categorize each animal’s consumption compared to her targeted intake. The sow record represents an animal whose consumption decrease would be flagged by the system.

Our software allows workers to better allocate their time in the barn, and low consumption reports can easily direct worker attention to potential problems or sick animals.

Similarly, by identifying the animals requesting large amounts of feed, adjustments for these sows can be easily made after determining if they are limited or wasteful sows and you can increase/decrease feed allowance, implement feeding delays, or change feeding schedules depending on the situation. The sow record would indicate an animal requesting large amounts of feed that could be potentially limited or wasteful (see graph below).

For additional ease of use, this consumption color code, on a daily average basis, corresponds with a colored LED light on each feeder to let workers know who needs attention.

Identify Feeding Opportunities for Lactating Sows

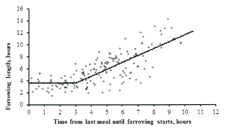

Gestal lactation feeders uniquely implement several feeding periods per day, and the idea is that sows who can eat more frequently, yet smaller meals will be capable of consuming more total feed than sows who eat larger meals only a couple times a day. In addition to improved feed intake for your operation, there is research, like this data presented by Feyera and others (graph below), demonstrating that reducing the time interval from the last meal to farrowing will also reduce farrowing duration. With a shortened farrowing duration, your operation could perhaps accomplish either better day 1 care or fewer stillborns.

Gestal aftermarket support is unrivaled, and with multiple swine nutritionists on staff, we are happy to visit with lactation customers on a quarterly or annual basis to review farm data and reports to help you maximize intake in lactation.

Is Feed Blending the Future in Pig Farming?

We do genuinely see feed blending in lactation as the next frontier in better feeding and meeting requirements in lactation.

We know that amino acid requirements vary throughout the lactation period, and animals will traditionally meet these requirements by adjusting their ADFI. However, there are certain periods of lactation when these requirements simply cannot be met by increasing intake. An example would be a first parity animal who cannot physically consume enough to meet requirements for both her own growth and milk production for the litter.

In particular, instances and periods of lactation where requirements are highest, we would propose feeding a more nutrient dense diet. In periods where requirements are lower, a less nutrient dense diet or a blend of the two could provide a substantial cost savings.

Picture a scenario where the feeder can automatically adjust blends based on previous days’ feed intake and number nursed to meet the actual requirements of the animal most accurately.

Thinking on into the future, if we compile ADFI records on an animal and # weaned in previous parities, we could calculate a lactational feed efficiency. We could feed sows more economically in future parities if we know how efficient she is in converting feed to milk.

Grow-Finish: Monitoring Feed Intake to Groups of Pigs

I’ll switch directions on you here again to discuss grow-finish or GDU precision feeding.

As I mentioned earlier, Gestal introduced the Evo Opti in 2019, and its intended use is for monitoring feed intake to groups of pigs. Additionally, it has also feed blending capabilities and can automatically adjust blends based on days of age, day placed, feed budgets, you name it. The software developers considered the many uses of this piece of equipment.

Of particular interest to us, there are the benefits that can be gained from a system like this in gilt developer units, where breeding animals are often fed only 2-3 diets during their entire growing period. The Evo Opti allows for gradual diet changes over time and can reduce both the amount of feed bins needed, as well as reduce labor inputs if gilts can stay in the same location until they are moved for breeding.

Overall, a goal of the Evo Opti is to better meet ideal nutrient requirements, which could result in higher gilt selection and retention rates. The ability to bring in sow vitamins and trace minerals earlier in a gilt’s life could improve longevity in the herd. Feed costs can be reduced since more expensive feeds can be phased out according to the precise timeline they are no longer needed.

In addition to the gilt development application, the Evo Opti can be used in commercial nurseries or grow-finish applications as well. The precision that Gestal customers can expect is also a great fit in research barns and is a great standalone alternative to some grow-finish research systems that are heavily mechanized and require frequent maintenance.

Multiple Dietary Treatments in Research Barns

You might be curious if such a hopper design and access to multiple diets are available in other areas of production, especially for research scenarios.

The “Opti” hopper, or the divided hopper that you see here that can mount on up to 4 feed lines, which can be used in lactation, gestation, and GDU as well.

This particular hopper is an excellent option for research barns where access to multiple diets or blends of diets is ideal.

Vision: Feeding and Herd Management Software

One thing that is on almost everyone’s mind is data integration, and we are proud to introduce the Vision software platform to integrate our data into farm or system-level reports. As an industry, we are acutely aware of the need for systems and software that integrate all collected data and report back to us the necessary and simplified information.

Vision software is our dashboard or data management tool that collects herd information in a meaningful format to streamline decision-making.

We are ready and prepared to share data with other record systems, and tools like Vision allow for single or multiple herd analysis, all from a common screen that can be accessed remotely.

Benefits and Features of VISION

Gestal users already use the mobile app to manage any and all feeding-related tasks, but there are several additional features that we have expanded on with the Vision software platform.

First, litter and farrowing information can be put in directly on the mobile to save time and eliminate the need for sow cards, also reducing the chance for errors.

All breeding events can be managed on the app, including pregnancy checks, heat number, service, and breed dates. Complete sow and parity history can also be managed directly from the software, making decisions like culling easier with a complete animal history. Lastly, easily share your data with external software such as accounting or ventilation programs.

Streamlining data entry and management is just one more way that JYGA Technologies is trying to capture more value for swine producers everywhere.

Improve your Performance with Precision Feeding Technologies

In summary, the adoption of precision feeding technologies and programs can vastly improve performance in multiple areas of production, from gilt development to gestation and lactation.

However, these technologies must be user-friendly and easy to implement because labor challenges are simply not going away.

The Gestal team encourages you to consider how implementation of Gestal precision feeding technologies could assist you in better feeding to actual animal requirements, as well as extend the value of quality employees with “management by exception”, or focusing on animals that need skilled attention with our automatically generated reports.

With that, I’d like to thank you for joining me, and I’m more than happy to address any questions you might have.

Questions & Answers

Can you Elaborate on Management by Exception?

Management by exception is a philosophy. Our industry is facing major challenges with labour, and they are going to be a consistent concern for us. We really believe, in using smarter machines, that either eliminate or reduce the need for manual tasks that use several hours of labour, for any given person.

A perfect example: a worker going out in the morning and taking the time to get every sow up. One thing that lactation feeder is doing, is delivering meals when a sow stands up and activates the trigger inside the bowl. It then reports that intake back to the feeder and would also notify us that she has essentially been eating for that period. What we are trying to do there is save someone the effort of getting every sow up, if we know that she is doing that job on her own by getting up and eating routinely.

More than anything, management by exception is essentially using workers’ time to focus on animals that genuinely need help, leaving others that are doing what they are already supposed to do alone and basically making good labour go a little bit further.

The concept of precision feeding during lactation is very intriguing, what logic is being used to determine the optimum lysine intake range by day of lactation for both gilts and sows?

A few of our team members have really spent some time digging into modelling. We have used some modelling based on the INRA Pork Model. What we have done is you would use things in your model like the number of pigs nursed, day of lactation, parity or genetics. Different things like that in the model would be able to tell you your SID lysine level is. Eventually developing an algorithm that could use the previous day’s average daily feed intake to tweak diets or manipulate blends of diets in lactation, to better meet the needs of these lactating sows.

For gestation in group housing, comment on major differences between the Gestal 3G system and traditional European ESF?

There are some advantages to European ESF. Sorting within pens for girls that might be close to farrowing; Those would be some options that come basically at the expense of some extra moving parts and mechanics of European ESF. These are highly mechanized which means that they require quite a bit of maintenance for the parts that wear out.

The Gestal 3G system is completely operated by the sow which is one of the things that was there by design. There are no mechanized parts in the stall. There is essentially a centralized pivot point, that sow operates by herself, there is a nylon bushing inside of that pivot point to prevent wear and tear over time. Again, she will operate that by herself, there’s no piston, no solenoids or different moving parts that we know overtime, in a barn situation, will go bad.

In my experience, I have seen ESF that allows other sows into stations before the previous animal has finished a meal. When different things are actuated by an air compressor or mechanize parts like solenoids, those will fail from time to time.

In Gestal 3G situation, sows are 100% protected while they are eating inside the 3G stations. There is no concern of an animal leaving before she is actually ready to leave. Your concern maybe that she will stay in those stations all day, by design we do not have water inside the station, most sows stay 30 to 45 minutes maximum, then they’re thirsty and they will generally go look for water right after they complete their meal. In our design, we also have an anti-lay bar so that the sow does not get too comfortable in the station.

The other big difference between Gestal and European ESF is that we generally promote multiple feeding stations for a pen. We would have a reduced ratio of animals per station where some European ESF can feed about 60 animals per station. We generally stay within the ratio of 15 to 20 animals per station. There really is not as big of a need for animals to eat quickly, they can take their time, and make sure it’s a good situation. Most of the animals, in Gestal 3G station, will be done eating about noon, you will see that the barns are generally pretty quiet in the afternoon.

Is there interest and value in precision feeding grow finishing pigs? What are the potential benefits and challenges?

It is obviously something that many people on the research side of things are definitely interested in. There are lots of different treatments that people wish to apply or be able to feed to answer their own internal questions. I assume that you are asking for more of a commercial perspective. Recently we have had the question brought up to us by one of the systems that we work with, whether they could improve the way that they market their animals by knowing the feed efficiency of a group of pigs by knowing when they will be able to market and improve their marketing process. There are a lot of different ways that you can look at it, from a commercial standpoint. There are major benefits to looking at precision feeding.

The one benefit that sticks out the most for me is precision feeding in the GDU. We really focus on how we can improve the growing process for a breeding animal. Obviously, we have sometimes on smaller farms many different lots of gilt and not many feed bins to feed them. If you can designate two bins, bring in an early GDU diet and a late GDU diet, you can blend based on programs and precision feeding for each individual lot within that. There is an opportunity to increase the retention rate and decrease the replacement rate of gilt substantially.

When do you advise to select gilts weight or age and start to feed them in a special gilts feed? How many phases do you recommend using, two or three?

I am probably not going to nail myself down to a specific answer because a lot will depend on your specific gilt flow and your genetics. For the most part, the more phases that we can fit in, especially with precision feeding, the better. I also do believe that it does need to be in a good combination of both gilt weight and age. Maybe we are growing our gilt a little bit too fast, and we need to slow it down. It does not have to be a race to the finish line. I encourage you to work with your genetic company that can provide nutrition and growing recommendations.

About the author

Amanda Uitermarkt is a technical service and territory representative for JYGA Technologies in the Midwestern US. She is a Tennessee native, but graduated from Kansas State University with a master’s in Swine Nutrition, studying under the Applied Swine Nutrition Team, in 2013. Her MS research was mostly focused on prediction of energy levels with reduced-oil DDGS and fiber withdrawal strategies prior to marketing.

From there she went to work for the Carthage System in a research capacity but gained experience in both sow and wean to finish commercial production as well as research while managing research on a 6000-head commercial sow farm and a commercial 4800 head wean to finish facility.

She has been with JYGA Technologies since January 2018 and she truly enjoy working with producers to improve their operations.

Additional information on precision feeding.