California Proposition 12: Navigating Facility Asset Options

A Builder’s Point of View on How to Comply

Guest author: AG PROPERTY SOLUTIONS

As California’s Proposition 12 (a.k.a. the “Farm Animal Confinement Initiative”) nears its January 1, 2022, implementation date, pork producers and other industry leaders throughout North America are trying to determine how this controversial and complex California law will ultimately impact them, as well as the pork industry as a whole.

This is especially the case for any producer looking to build new facilities, expand their existing operations, or sell product to California, or plan to sign a contract to sell into California in the future. There is an array of different factors to consider when undergoing any facility construction. However, given the intent and pending implementation of Proposition 12, the stakes are even higher going into the future.

As a company that provides a full range of planning, design, construction, and maintenance services for pork producers, there are some critical questions for you to be aware of (and answer) if you are looking to grow your operations – all while keeping the proposed guidelines of Proposition 12 in-mind.

1. Do you wish to maintain or reduce herd size based on existing structure constraints?

Many older facilities with gestation stalls are in the 14 sq. ft./animal range. Increasing from 14 to 24 sq. ft./animal is a 70% increase in space for most existing facilities, assuming similar walkways or that the square footage of the walkway stays the same.

Reducing herd size

If you are reducing herd size, you must also consider the quantity of farrowing crates you currently have and how that relates to your gestation herd size.

Maintaining herd size

Most customers focus on maximizing the number of animals in the gestation barn. However, this is generally at the expense of labor and animal management considerations. A successful decision-making process must always include owners, management, and labor to ensure the best situation for all vested parties.

2. What do you do about the farrowing crates?

- What do you do with the extra farrowing crates if the gestation herd is reduced?

- Will farrowing crates and flooring platform specifications be mandated similarly to gestation animals in the future, creating new standards and obstacles?

Farrowing crates – and how they fit into the puzzle – are relevant and important to consider. And, based on what we know and given the spirit of Proposition 12, there is reason to believe that the existing 5’ x 7’ farrowing platforms will not be large enough. Given this information, your current quantity of farrowing crates per room will be reduced to something less if new guidelines are created and once the final rules are published.

Current discussions have centered around a minimum of 48 sq. ft. flooring platform area with a turnaround farrowing crate. However, there are no clear details on what the guidelines or rules will be in the future. So, assuming the 48 sq. ft. flooring platform area becomes the accepted standard, this equates to approximately 37% more space required than many existing farrowing facilities.

Regarding animal flow, if you believe this is the future, carefully evaluate the reduction in gestation herd size and farrowing crates. This, taken into account, with the higher PSY (pigs per sow per year) levels, may get you back to an animal production level more consistent with the design of the original sow complex.

On the other hand, if you wish to maintain herd size and production levels, here are some suggestions on how you can find the space to house all gestation animals within the 24 sq. ft./animal guideline:

- Expand your existing barn(s). Stay with the same width or modify measurements to facilitate the best layout options.

- Build an additional new gestation barn and interconnect the walkways.

- Build a new gestation barn designed to match the current requirements and remove the old gestation barn(s).

3. Do you build a new facility or reuse an existing facility?

Building new or enhancing an existing facility is always a hard choice – one that frequently comes down to cost and/or timing.

If you are building from the ground up at a new site, the benefits of a green, design-to-fit building are self-explanatory. This option offers the opportunity to add all the design and technology features needed to meet any number of industry and/or governmental requirements.

Removing an existing barn and replacing it with a new facility is also a possibility. Still, you must make site considerations that include manure and nutrient management as a starting point. With some clients, we have found ourselves demolishing several old barns to build one new barn to maximize site restraints and allow for the best labor practices.

Reusing and retrofitting an existing gestation building is also an option. However, the slat configuration (i.e., partial slat or total slat) of your existing barn is important and plays a critical role in animal flow and overall cost.

For example, partially slatted barns with 8’ wide slats are challenging to design around when using Free Access Stalls (FAS). Additionally, partially slatted barns can be particularly challenging to design because the animals in the FAS need to be over slatted portions to minimize dirty animals and maintain a 24 sq. ft./animal space. Generally, these barns have “poured in place feed troughs” that need to be filled in.

In some cases, there are feed troughs above the flooring that will need to be removed. Some partially slatted barns also have solid walkways poured on top of the existing flooring that need to be removed, and partial slat barns also tend to have floors that slope from the alleys downward towards the slats. Given this information, gating and FAS must be designed to work with these different elevations.

On the other hand, total slatted barns offer much better flexibility when it comes to design options that maximize animal capacity and flow.

4. Do you have room to add to your existing barn to allow for 24 sq. ft./animal?

Many of the old gestation barns were designed with shallow pits. If this is your situation, a key consideration is whether or not your current manure system will work if you add to the existing barn and maintain a half percent slope in the piping system.

But, if your existing gestation barn is a deep pit design, we suggest securing a licensed engineer to determine if the soil can be removed from the concrete wall (without collapse) and if expanding the existing pit is feasible.

As a part of this process, you will generally need to create a hole to transfer materials in the pit to equalize water pressure on both sides of the wall.

Where and how can you layout the Free Access Stalls (FAS) for best animal movement and best labor practices?

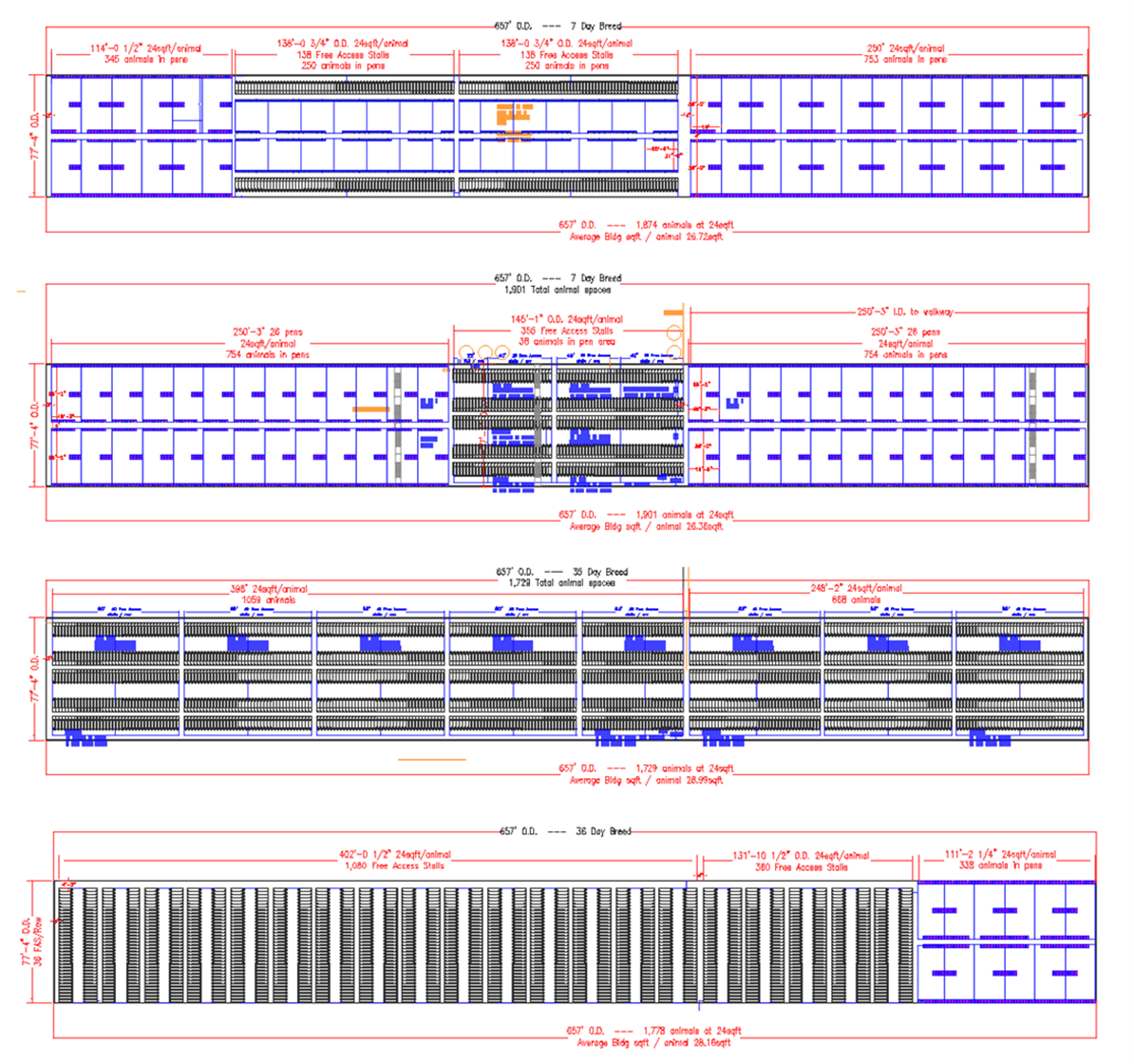

Determining the layout and design of your FAS is a critical part of any new or existing building, as it directly correlates to your operations’ overall success and efficiency. See the various design examples below.

Proposition 12 Design Options

Do you consider FAS an open pen system?

Most producers that we work with believe FAS represents an open pen system. If you agree with this assessment, you will need to determine if you wish to use pre-implantation breeding timing (e.g., generally 3 to 5 days in FAS, then back into conventional pens), which equates to approximately 11% of gestation animals. Or, if you use post-implantation breeding timing (e.g., generally 35 to 40 days in FAS, pregnancy check, then back to conventional pens), that equates to approximately 40% of gestation animals.

But, if you do not believe FAS to be an open pen area that allows for more than a 2 to 3 hour retention time, the question is, what is your best practice to find animals in heat? Old systems utilized breeding squares. Once heat is detected, animals are moved to a short-term stall of some nature for artificial insemination. No matter the selected method, determining the best and most efficient way to breed animals is critical to the overall success of your ongoing operations.

Furthermore, as producers consider their operations, the most optimal feed system design and nutrition plan needs to be closely evaluated. Post wean/pre-breeding animals require a much different strategy than post-breeding animals. Again, it is critical to work with a trusted partner to determine the best practices for your nutrition and facility goals.

Do you have sufficient heat in the barn?

In the past, standard density gestation barns required minimal heat to maintain a comfortable environment for the animals – relative to the region. The change from the common 14 sq. ft./animal space to 24 sq. ft., represents less animal density, thus it requires approximately 42% more heat for the same building. As a general rule of thumb, a producer should plan for about 50% more heat for a 24 sq. ft. barn than an existing 14 sq. ft. facility. However, there are many factors that need to be evaluated for an optimal HVAC environment, and it is best to solicit a professional recommendation based on your exact barn specifications.

Final Thoughts.

At present, Proposition 12 appears to be a significant “game-changer” in the world of pork production, but how it will be implemented, enforced, and accepted within the industry remains to be seen. What legal challenges it attracts – both current and future – is another factor that needs to be watched closely.

In the meantime, producers of all sizes need to pay close attention to the issue yet also understand that viable, cost-effective, and efficient options to build new and/or modify existing production facilities exist and can be attained with the help of a trusted partner and the right amount of planning.

For more information on the products, services, and expertise provided by Ag Property Solutions, visit www.agpropertysolutions.com.