Customer’s Testimonial: GESTAL Feeding System Transforms Pig Farming Efficiency

Discover how the owners of DV Pork Farm achieved remarkable results with precision feeding.

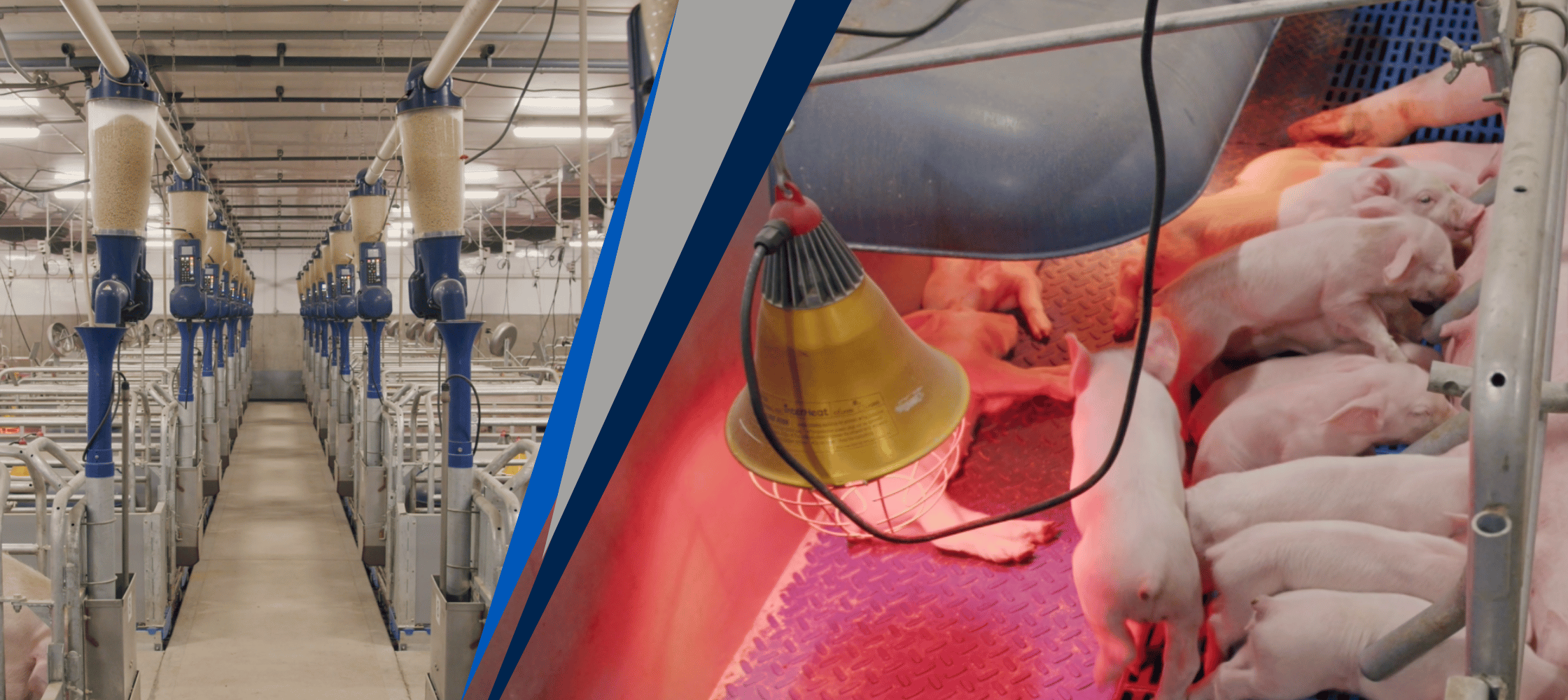

In this father-daughter testimonial, Daniel and Noémie Vachon, pork producers from Québec, Canada, share their transformative experience with GESTAL technology in their 1,400-head sow farm. They retrofitted their gestation barn in 2020 to meet animal welfare standards and integrated GESTAL systems, including GESTAL Solo+, GESTAL Quattro, and GESTAL 3G, into their operations.

Feeding System Boosts Litter Size

Before the retrofit, DV Pork Farm produced approximately 26 weaned piglets per sow annually. However, after adopting the GESTAL feeding system, this number soared to an impressive 33.25 weaned piglets per sow per year. This remarkable improvement positioned them as the second-best farm in Canada according to PIC classification.

The Vachon family attributes much of their success to GESTAL’s user-friendly technology, increased sow feed consumption, and heavier weaning weights. The outstanding service from JYGA’S tech team also contributed to the success of the farm.

A Solution for Labor Shortage

“With computerized feeding, we were able to go from 1 employee per 300 sows to 1 employee per 400 sows” claims Noémie Vachon.

They highlight the substantial labor efficiency gains, reducing their employee-to-sow ratio from 1:300 to 1:400, which significantly alleviated the challenges posed by labor shortages in the industry.

Precision Feeding and Smart Management to Help Improve Overall Farm’s Performance

The GESTAL smart feeding system allowed employees to precisely tailor feed quantities to meet each sow’s specific needs, minimizing wastage amidst rising feed prices. In the gestation barn, the free access ESF (electronic sow feeding) station facilitated gilt training, with an impressive 90% success rate in sow self-training. The remaining 10% of non-feeding sows can be attributed to first time users. Fortunately, they can easily be identified using the office computer and then assisted by farm employees.

GESTAL Quattro: A Valuable Ally in the Farrowing Room

The capability of the GESTAL Quattro to regulate heat lamps optimized the farrowing procedures, allowing the management team to have better control over their time and priorities. Piglets are separated and weaned once they reach a healthy weight of 6.5 kilograms (approximately 13 pounds) after 21 days.

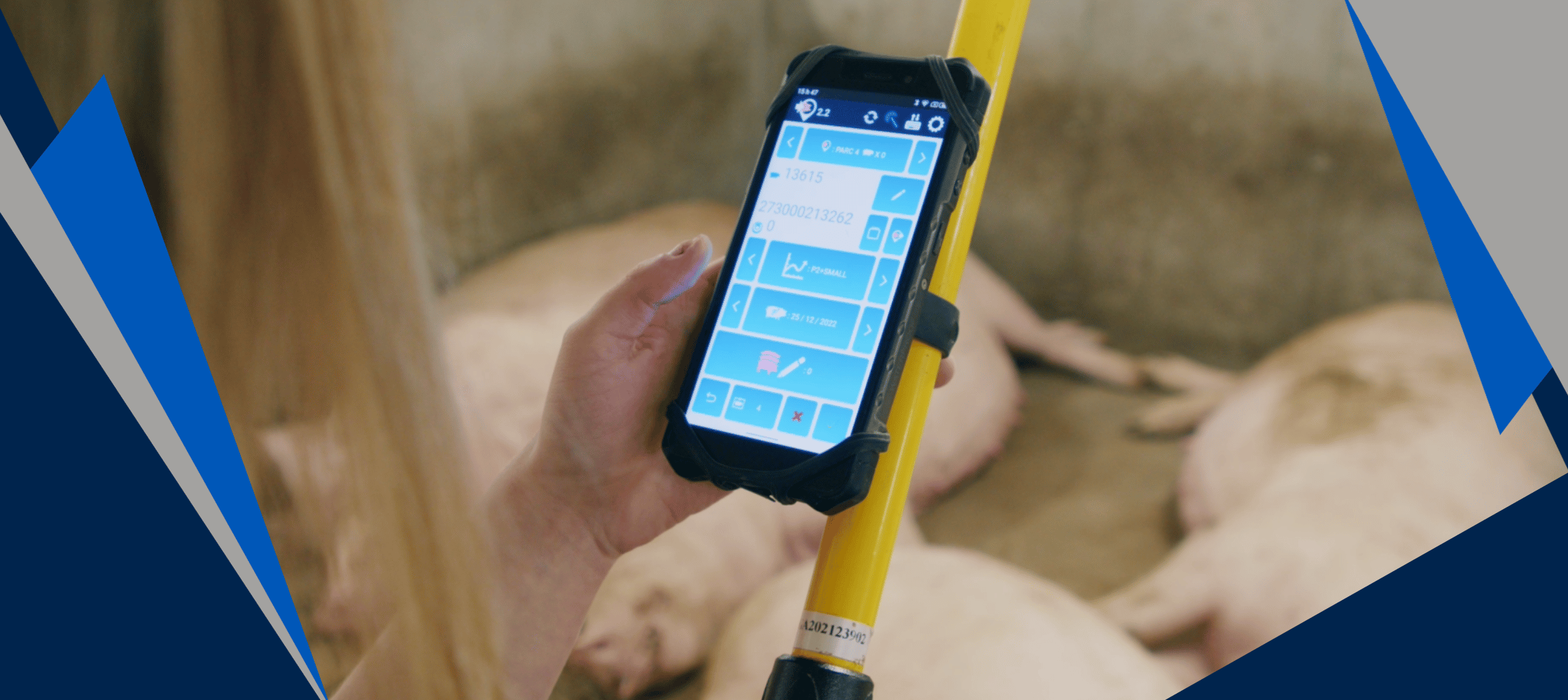

Utilizing Data from VISION Software for Informed Decision-Making

To manage their data efficiently, the team uses VISION software, which simplifies data collection. The software’s historical sow data aids in culling decisions, while production statistics enhance decision-making on the farm.

Embracing Technology for the Future

In conclusion, the owner of the farm has been a dedicated pork producer for 25 years and is enthusiastic about leaving the GESTAL feeding system to the next generation. The team passionately believes that technology is the future of farming, offering solutions to labor shortages and making it easier for the younger generation to work on the farm. JYGA Technologies, the provider of GESTAL smart feeding systems, takes pride in contributing to the success of DV Pork Farm.

Should you desire to enhance your farm’s efficiency by implementing a smart feeding system, reach out to our team of specialists. They are well-equipped to advise you on the benefits of GESTAL in optimizing your operations and ensuring your peace of mind.